Enamel pin Information

Made by @HannyaTiger on most platforms

(@HannyaTiger_ on X/Twitter)

Special Thanks to Pytress and the others who helped me make this!This is an Informational Carrd dedicated to explaining the art of making enamel pins, what you can do to make them more unique, and the struggles that come with it.

BASICS

What are enamel pins, and how do I get them made?

A lapel pin, also known as an enamel pin, is a small pin worn on clothing, often on the lapel of a jacket, attached to a bag, or displayed on a piece of fabric. In recent years, pin collecting and trading has also become a popular hobby. Demand for pin designs based on popular cartoon characters and themes such as Disney, Betty Boop, and Hard Rock Cafe has surged and led to the creation of pin trading events and other social activities. Disney pin trading is a prime example of this. (From This Wikipedia Article)

Pins can vary in size, some of the smallest being 0.25 inches, while some of the largest from my experience being around 3 inches to 4 inches in size. Yet the most common size of pins are 1 to 2 inches in size. You can also get a variety of extra additions on a pin to make it more unique, which I'll explain in heavy detail later.

Enamel/Lapel pins are most often made by manufacturers in quantities of 100+ pins or higher per design, this is mainly so the artist who make the pins can get their moneys worth. Technically speaking, you could get a singular pin of a singular design, but due to the cost of the mould which can be very expensive, you won't find many manufacturers who allow this due to said cost. The smallest quantity you can get commonly is around 25-50 pcs per design.

The best place I can recommend you look for enamel pin manufacturers is Alibaba.com, as thats the most direct way you can contact suppliers, though, with that comes its own issues. Due to most pin manus coming from China and other non-english countries, there can be an problem with communication. The best way around this is to not use any slag and stick to being direct, as most times if the Manu doesn't understand english, they'll use Google Translate to convert any messages to their language.

If you don't want to risk any miscommunications and such you can always go to a "middle man", the most common example of this is Vograce, as last I've heard they don't make Enamel pins in house, though, That could be outdated information, so don't take my word for it. But even with middle mans the whole back and forth process of getting production proofs done and needing any edits made could take longer, especially if the middle man is as popular as Vograce is. For those unaware, Vograce is both an Acrylic manufacturer and a possible middle man for other more complex products they offer on their website, and is one of the more well known manufacturers when it comes to the art community.

What is the difference between soft enamel and hard enamel?

Hard enamel pins are sanded down before the plating process starts, this helps give the pin a smoother finish, but can also cause the lines to be thicker. Hard enamel pins aren't recommended for heavily detailed pins that wont rely on printing to get smaller details done.

Soft enamel pins are when the casing is filled to 99%, after the base has been polished and plated, and does not get a second polishing once the enamel is dried. But due to not being sanded down pre-plating process, it allows for more heavily detailed pins. Though, this method is still used for pins that would be perfectly fine with hard enamel by some artist.

Only some metals can be used with Hard enamel, there are certain metals that cannot be or aren't oftenly used with Hard enamel due to the process of making the metal itself or other reasons that could affect the process. A list of metals that can be used by Soft Enamel, Hard Enamel, Both, will be listed below. It should be noted that some manufacturers do not mind using metals that aren't usually used for Hard Enamel to make Hard Enamel pins.

| Soft Enamel | Both Enamel |

|---|---|

| Antique Copper | Copper |

| Antique Silver | Silver |

| Antique Brass | Brass |

| Antique Gold | Gold |

| Antique Nickel | Black Nickel |

| Antique Tin | Rose Gold |

| Rainbow Plating | |

| PMS Dyed Metal | |

| Chrome (With exeptions) |

How can I make my enamel pins more Unique?

Paint Customisation

| PEARLESCENT |

|---|

| "Pearl effect enamel lapel pins have hidden marble textures, which create unique color patterns in each piece. Basically, it is imitation hard enamel colors mingled with a special color paste to generate color swirls." |

| You also have two different styles of pearl powder, the one shown in the example image is swirled, which gives the enamel a marbled look. The other style you can get is where the pearl powder is fully mixed into the enamel, giving it an even shimmery tone without the ripples and marble effect. |

| Note that these colours are just from this manu, and different ones can have more variety. |

| Explination/image source: jinsheu.com |

| This type of enamel paint can be used in a variety of ways, I've seen usage by PrinceFizz with their Princess Celestia enamel pin design. They utilise the pearlescent enamel paint to represent Celestias shiny, wavy mane, using four separate colours. |

| GLITTER |

|---|

| "With glitter pin badges, we mix the glitter into the enamel before adding it to the metal base. Because we bake the glitter into the enamel, there's no glittery mess like you'd find on a jazzy birthday card or your 6-year-old nephew's latest art project. Once the pins are baked and polished, the glitter elements catch the light, giving your pins a dazzling finish." |

| Explanation source: madebycooper |

| Image source: TheHaywaiianHorse |

| It should be noted that this Luna pin isn't (?) available to buy anymore, but its still a good example to use. |

| STAINED GLASS/TRANSPARENT ENAMEL |

|---|

| "Plique-à-jour is a technique used to make enamel resemble stained glass. This is achieved by adding the enamel powder into a cell backed by a sheet of copper foil or a similar metal. The enamel is fired, and then the sheet is removed with a light tap or acid. The enamel that remains is shimmering and translucent." |

| There are of course a variety of other ways translucent enamel can be made, the methods vary manufacturer to manufacturer, so this is just an example of one of many methods. |

| Explanation source: GIA |

| Image source: PrinceFizz |

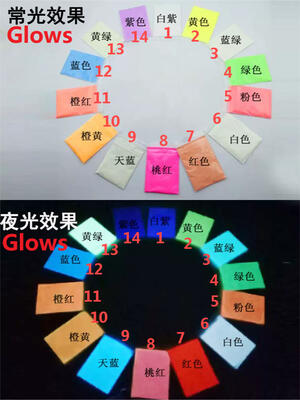

| GLOW IN THE DARK |

|---|

| "Glow in Dark Effct which translates to “luminous in the dark,” allows materials to emit light in dark environments. By incorporating special chemicals into materials, lapel pins can absorb light during the day and glow in the dark. This not only enhances the visual appeal of the pins but also increases their functionality, especially in pin design." |

| Pin Image source: TheHaywaiianHorse |

| Image (GITD colour examples) and explanation source: HIPins |

Printing

| There are three major printing types, though I do believe there are a few more, these seem to be the most commonly used. All pins shown in this section use Screen Printing. |

| Screen printing |

| "Screen printing is a popular printing method used for custom enamel pins. It involves creating a stencil of the design, which is then used to transfer the ink onto the enamel pin. This method is suitable for designs with simple shapes and limited colors, and it produces a vibrant, long-lasting print that is resistant to fading or scratching. Screen printing is also cost-effective for large orders, as the cost per pin decreases with the quantity ordered. |

| However, screen printing has some limitations when it comes to complex designs and fine details. It may not be suitable for designs with gradient colors or photographic images, as it cannot produce the same level of color accuracy as other printing methods. Additionally, the printing process may not capture every detail of the design, resulting in a less precise final product." |

| Offset printing |

| "Offset printing is another popular printing method for custom enamel pins. It involves transferring the design onto a metal plate, which is then used to transfer the ink onto the pin. This method is suitable for designs with fine details and multiple colors, and it produces a high-quality print with excellent color accuracy. Offset printing can also be used for a wide range of pin sizes and shapes. |

| However, offset printing is more expensive than screen printing, particularly for smaller orders. It also requires a longer setup time, making it less suitable for rush orders. Additionally, offset printing may not be suitable for designs with metallic or glitter effects, as it cannot produce the same level of texture as other printing methods." |

| UV printing |

| "UV printing is a newer printing method that is becoming increasingly popular for custom enamel pins. It involves using ultraviolet light to cure the ink onto the enamel pin, resulting in a durable, high-quality print that is resistant to fading and scratching. This method is suitable for designs with fine details and multiple colors, and it can produce a wide range of effects, including metallic, glitter, and neon. |

| UV printing is also more environmentally friendly than other printing methods, as it does not use solvents or produce harmful emissions. However, UV printing is more expensive than screen printing, particularly for small orders. It also requires a longer setup time, making it less suitable for rush orders." |

| Contradicting some of what was said, apparently UV printing can come out choppy and visually grainy. Some pin collectors consider UV printing low quality and due to this undesirable. |

| Information source: YourStuffMade |

| Image source: VernilleArt |

metal Plating options

| COMMONLY USED PLATING |

|---|

| The image of a chart I show here shows all the different types of metal and the variations of metals that you can use to make pins! It should be noted these metals can be used for both hard and soft pins, but for special methods like PMS dyed metals (dunked in enamel after the metal piece is made), that can only be manufactured with a soft enamel method. Though, you can get printing on the metal, as seen with the Bluey pins in the Complex Customisation section. |

| I've been told that you aren't able to mix hard enamel with rainbow plating due to something called electrolysis, the Oxford Dictonary states this as the definition: "chemical decomposition produced by passing an electric current through a liquid or solution containing ions." |

| Image source: The Pin Factory |

| CHROME PLATING |

|---|

| "Its a very specialist process, the pin is bathed in acid and electrified to create the colour. The most accessible version of this process is rainbow plating, which you might have seen before and that more manufacturers will do because it's easier to create the rainbow effect than one solid colour." |

| It should also be noted that due to the process of making the metal a specific colour, and how complex the process it is, it can have alot of B-grades, and not many Manus offer this type of plating (Other than rainbow plating). |

| It should also be noted that only a handful of manufacturers do hard enamel chrome pins, because it uses a non-enamel polymer to get the effect of a hard enamel pin! |

| Explanation/Image source: A conversation I had with the lovely PrinceFizz! |